Watering Down a Stope

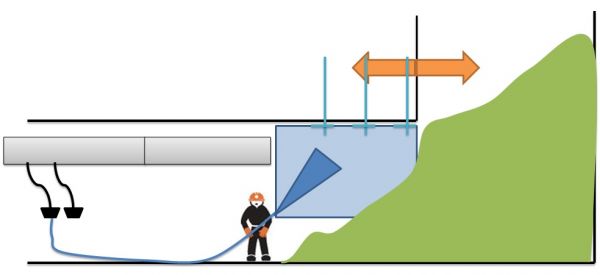

Watering down a stope

Once the firing is complete and the stope has been re-entered APMS then the watering down can commence using the following steps:

Check for hazards and that the secondary ventilation is working

Run out the water hoses.

From the end of the vent bag water the walls down on the way in.

Once at the dirt set up the hose to water down the stope being careful to stay well behind the unsupported ground, APMS.

The brow is the corner where the ore drive meets the stope and is one of the most dangerous places in the mine. Most mines have an APMS rule about how far back you have to be from the brow always make yourself aware of the standards of the mine you are working on.

Set up the hose on the ground and direct the spray as high as possible.

Turn the hose on slowly, if you turn it on too fast then the hose may move causing it to fly everywhere.

The hose can be left for 20 – 30 minutes before changing direction.

It is important to watch the stope at all times incase there is any movement, if there is movement then retreat out of the area ASAP

The hose can be left to run in one spot for 15 minutes then moved to another and then repeated. Depending on the size of the stope it can take 1 – 2 hours to finish watering.

Water the backs down on the way out the same as you would for a heading.

When the watering is complete the bogger operator and shift boss need to be notified