Skills of the Workers

The Skills of the Workers

When working in a hazardous workplace how does the skills of the workers help make the workplace safer?

Spotting the hazards;There used to be a poster that was put out by the WA Mines Department the statement was simple “look up and live”. When going into a new mine that may have low safety standards always keep an eye on the backs. In some countries mesh and shotcrete is not used, this is not a huge concern as long as there are bolts in place and you can see rattle marks in the backs. This was the method we used to mine with only 15 years ago. It is still a safe method as long as it is carried out correctly.

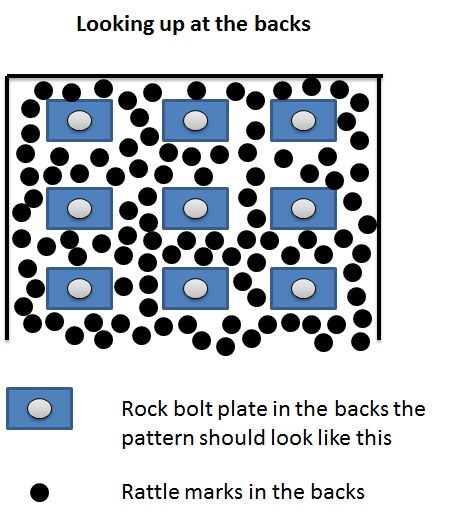

Fixing the hazards; What is a rattle mark? When a jumbo scales the backs, or rattles down as it is sometimes called, the jumbo drills into the freshly fired backs like they are starting to bore a hole. If the rock is loose then this rattling down will bring down the loose rock. The reason you should be looking for the rattle marks is because if the backs are safe there will be short holes (rattle marks) in the backs. If the rock joints are intact then the drill will start boring a hole. The jumbo operator will then move the boom slightly and start rattling again, it should look like this.

If there are no rattle marks in the backs then you need to get out of the area as quickly as possible. If there are rattle marks in the backs and rock bolts in the backs then it’s safe to stand there but as we will talk about in the scaling section, always stand under the supported ground. If there is no mesh or bolts, the best place to stand is directly under a rock bolt,

Having the confidence to stop the work; Sometimes as a contractor on site you may be asked to do things that you may feel is unsafe, an example of this is when working on a jumbo or long hole never go out to the front of the machine while it is working as in the early 90’s there were many cases of equipment and loose clothing getting caught in the drill causing death (being skinned alive) to the person caught in the drill. If trying new bits or steels make sure the machine is stopped before going past the front jacks. If you feel that you are in an unsafe environment then please don’t go into the area.

In other words, their skills control the hazards in the workplace.

So in order to achieve a safe workplace, the worker needs to not only believe that a safe workplace is possible they must also have a broad understanding of the job and a belief in themselves to carry out the job safely.

When management tells the workers that a 000 work site is achievable, what is the worker hearing?

That management has confidence in the workforce.

That they believe it is possible and will do what is required to meet this target.

This creates a positive way of thinking about safety. In a hazardous workplace we have the skills required to meet the challenges that will inevitably occur.

Underground Training has developed a list of positive ways that can help you make your workplace safer.