Paste Fill

Paste Fill

Once again one of the engineers will be working on this project full time. Often there is a leading hand to work and instruct the workers, these people can be very helpful and are often a good resource.

Once the stope has been bogged out then we refill the void with paste, this is left over tailings from the mill mixed with water and 5-7% concrete.

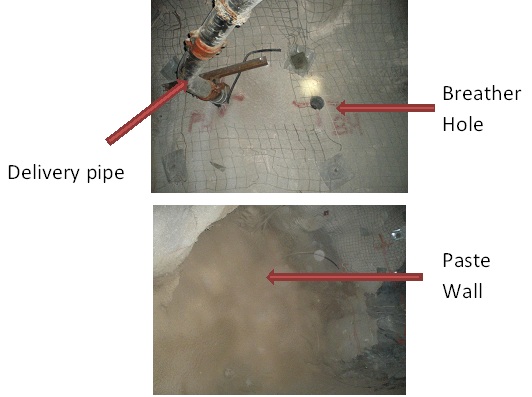

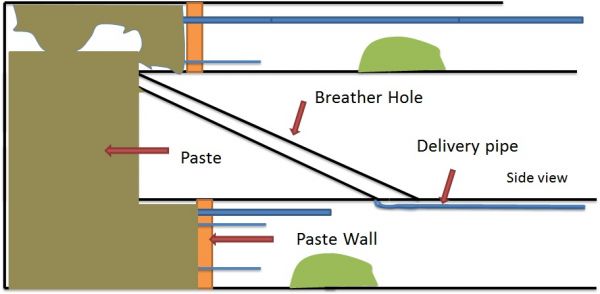

This is called paste and fills the void, once setting it allows the pressure to run through the rock again instead of having to go around the void which can create an unstable environment in the mine. The process of filling the stope with paste is to first build a paste wall out of a steel frame covered with mesh and then sprayed to a thickness of 200mm. The long hole then enters and bores the paste and delivery hole for the paste. The last thing put into place is the bund wall (3 buckets of hardrock), normally 1.5m high to contain the paste if the paste wall was to fail.